描述

High-end Wave Soldering Machine

Features

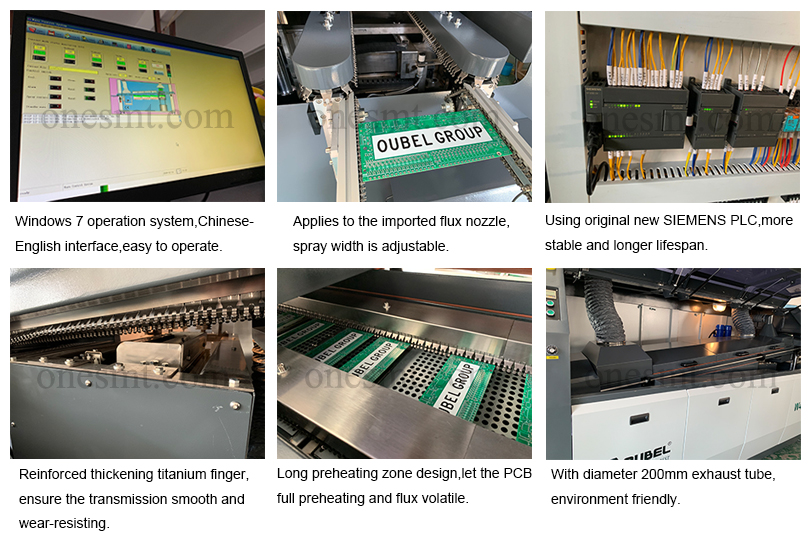

1.Windows 7 operation system,Chinese-English interface ,easy to operate.

2.All production data can be backup automatically,which is convenient for the ISO 9000 management.

3.Enjoy the intelligent diagnosis function,it can display ,alarm the trouble and store them.

4.There is special brush in the finger box, it can clean the finger totally.

5.Cross-flow fan design ,which can make the twice forced air cooling.

6.High power forced air cooling system, make the PCB cooling speedy.

7.Built -in rectfier system,uniform wind speed, uniform cooling.

8.Module transportation system,the entire tooth box type structure,which makes the transmission smooth.

9.Reinforced titanium finger, hard to out of shape.

10.Both of two waves width can be adjustable,minimize the oxidation of the tin oven.

11.Backflow slot design,which can gathered the tin slag automatically to one side of the oven.

12.Standard full titanium soldering pot more suitable for the lead free production.

13.1/2HP high power motor,meet the wave length up to 15mm.

14.PLC+PID closed loop control,more stable and higher repeativity precision.

Specifications

| Model | OB-W450-PC | |||||||

| Dimensions | 4600*1550*1650mm | |||||||

| Weight | Approx.2300KGS | |||||||

| Power supply | 3P5W 380V/220V 50/60HZ 63A | |||||||

| Start up Power | 26KW | |||||||

| Operation Power Consumption | 8KW | |||||||

| Control System | PC+PLC | |||||||

| Spray System | ||||||||

| Transmission Method | Step motor/Air cylinder(optional) | |||||||

| Spray pressure | 0.25MPa-0.4MPa | |||||||

| Flux Flow Arrange | 10-100ml/min | |||||||

| Auto Fill Flux | Automatic | |||||||

| Exhaust | Up&Down Exhaust | |||||||

| Exhaust Ducting Diameter(mm) | θ200 | |||||||

| Exhaust Capacity | 25m³/min | |||||||

| Preheating system | ||||||||

| Preheating Mode | Hot air/IR tube (optional) | |||||||

| Control mode | PID+SSR | |||||||

| Preheating Zone Number | 4 | |||||||

| Preheating Length (mm) | 1800 | |||||||

| Preheating Temperature(℃) | Room Temperature-250℃ | |||||||

| Warm Up Time(min) | Approx.15 min( setting: 150℃) | |||||||

| Conveyor system | ||||||||

| PCB Width(L*W)mm | 80*60- 500*450 | |||||||

| Conveyor Direction | L-R or R-L | |||||||

| Conveyor speed(mm/min) | 0-2000 | |||||||

| Conveyor Height(mm) | 750±20 | |||||||

| Available Component Height | Top: 120 Bottom: 15 | |||||||

| Conveyor Speed Control Mode | Closed loop | |||||||

| Finger | Quick-changefinger(standard) | |||||||

| Conveyor Width Control | Manual/Automatic (optional) | |||||||

| Conveyor Angle | 4°-7° | |||||||

| Soldering System | ||||||||

| Solder Pot Style | Motor drive | |||||||

| Solder Pot Material | Full titanium/Cast iron (optional) | |||||||

| Wave Height Adjust | Digital control by PC | |||||||

| Heater Power | 380V AC 9KW | |||||||

| Solder Pot Temperature | 300℃ | |||||||

| Solder Pot Capacity | 400KGS | |||||||

| Wave Drive Power | 2KW 220V | |||||||

| Solder Pot Warm-up Time | Approx.180 min(setting: 250℃) | |||||||

| Temperature Control Mode | PID+SSR | |||||||

| Cooling System | ||||||||

| Cooling Method | Forced air/Air cooler(optional) | |||||||

| Others | ||||||||

| Finger Cleaning System | Brush | |||||||

评价

目前还没有评价